01

Block selection Processing

When selecting stone blocks for a project or a product, there are several factors Borrowed Earth considers, including the intended use of the stone, the desired appearance, the location and climate of the project site, and the budget.

Our supply of natural stone and marble is finite, Like all of the earth’s natural resources — meaning at some point, we will use up all of the reserves in our pursuit for luxury. As demand continues to increase, protecting the supply of these, and utilising these in the most efficient is our primary objective while selecting our materials.

Different types of stone have different strengths and weaknesses, and are better suited for certain applications.

The location and climate of the project site also impacts the stone block selection process. Some types of stone may be more prone to weathering or fading in certain climates, or may not be suitable for use in areas prone to freezing temperatures.

02

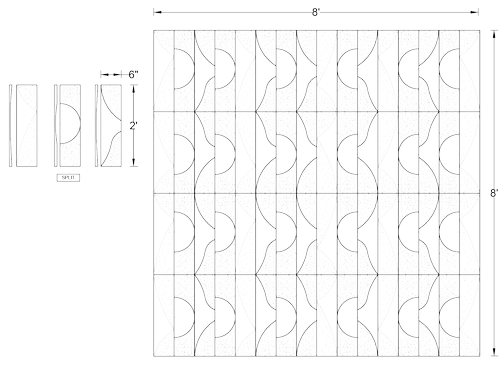

Texture and Pattern modeling

Our designers typically start by sketching out their ideas on paper or using 2D computer graphics software. This is then used to build a 3D model of the pattern, using a variety of modeling techniques, such as extrusion, revolution, and lofting.

Pattern modeling in 3D refers to the process of creating digital models of patterns or textures in three-dimensional space. This is done using computer-aided design (CAD) software, such as AutoCAD, 3ds Max, or through the use of 3D scanning and modeling tools. The accurate, realistic representations of patterns and designs thus created are then used for prototyping, visualization, and manufacturing.

Once the model is complete, it is rendered using computer graphics techniques to create a realistic, photo-realistic image of the texture or pattern which helps our team in visualizing how the pattern will appear in different lighting conditions and materials.

03

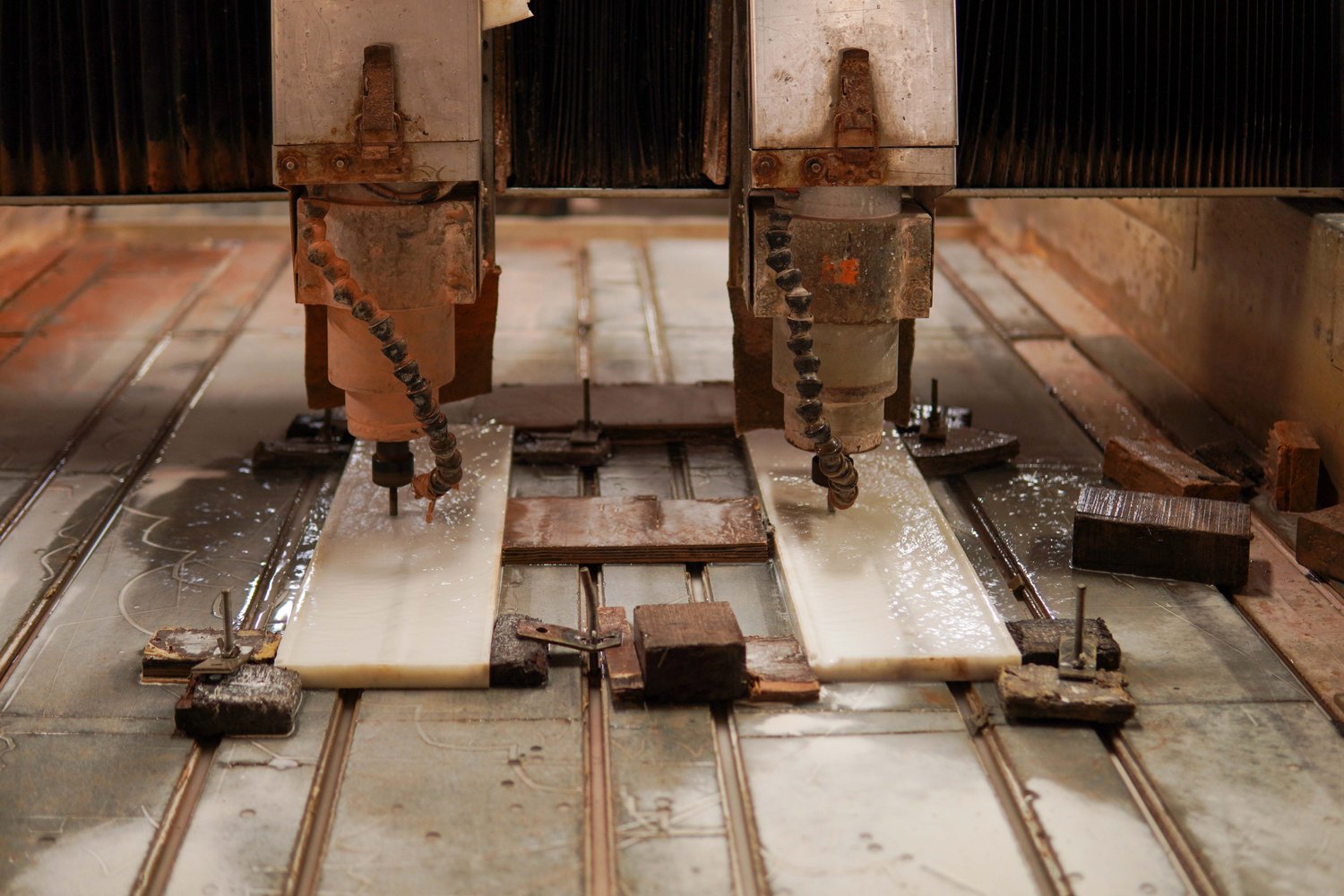

Robotic Manufacturing

The detailed texture and pattern models created by the design team is programmed to carve intricate patterns and textures into marble surfaces, and create highly precise cuts and shapes that would be difficult to achieve by hand.

Borrowed Earth uses robotic manufacturing to create architectural surfaces is by utilizing advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create highly detailed and complex designs that would be difficult or impossible to achieve using traditional methods.

04

Craftsmanship and Smoothening

The individuality of each piece is celebrated and respected, allowing nature to flow into our spaces.

The final intervention involves craftsmanship and smoothening, which is a combination of technical skill, artistic ability, and attention to detail.

Each individual tile and slab, is obsessed over by our team of skilled craftsmen who, painstakingly hand-finish and smoothen out, using hand brushes the tool marks, striations, selectively, based on the desired effect of each texture and pattern.